3Include and discuss other factors affecting choice of material such as cost availability of materials processing welding joining etc. Designing building and testing composite structures and pressure vessels since 1982.

Advanced Aerospace Structures Lecture 4b Composite Pressure Vessel Netting Theory Youtube

DESIGNING A COMPOSITE MATERIAL PRESSURE VESSEL FOR MANUFACTURE.

. Composite Pressure Vessels CPV play an important role in the emerging market for the fuel cell electric vehicles but there are also numerous more traditional application areas for CPVs. In order to reduce the thickness of the pressure vessel without affecting the performance of the vessel composite material were used. Ad Filters Heavily Used In Aerospace Support Flight Applications.

This project is proposed to analyse and design a cylindrical pressure vessel made up of composite material. Composite pressure vessels tend to fail in their composite pressure vessels parts. Prediction of the ultimate strength of a designed vessel is done using various failure theories.

At present the outer shells of the pressure vessels are made up of conventional metals like Structural analysis will be done in ANSYS on the pressure vessel. Because of the additional composite failure modes for COPVs deter. The focus of this research is to evaluate the reliability of pressure vessels made of composite materials carbon and glass fiber with respect to stress and burst.

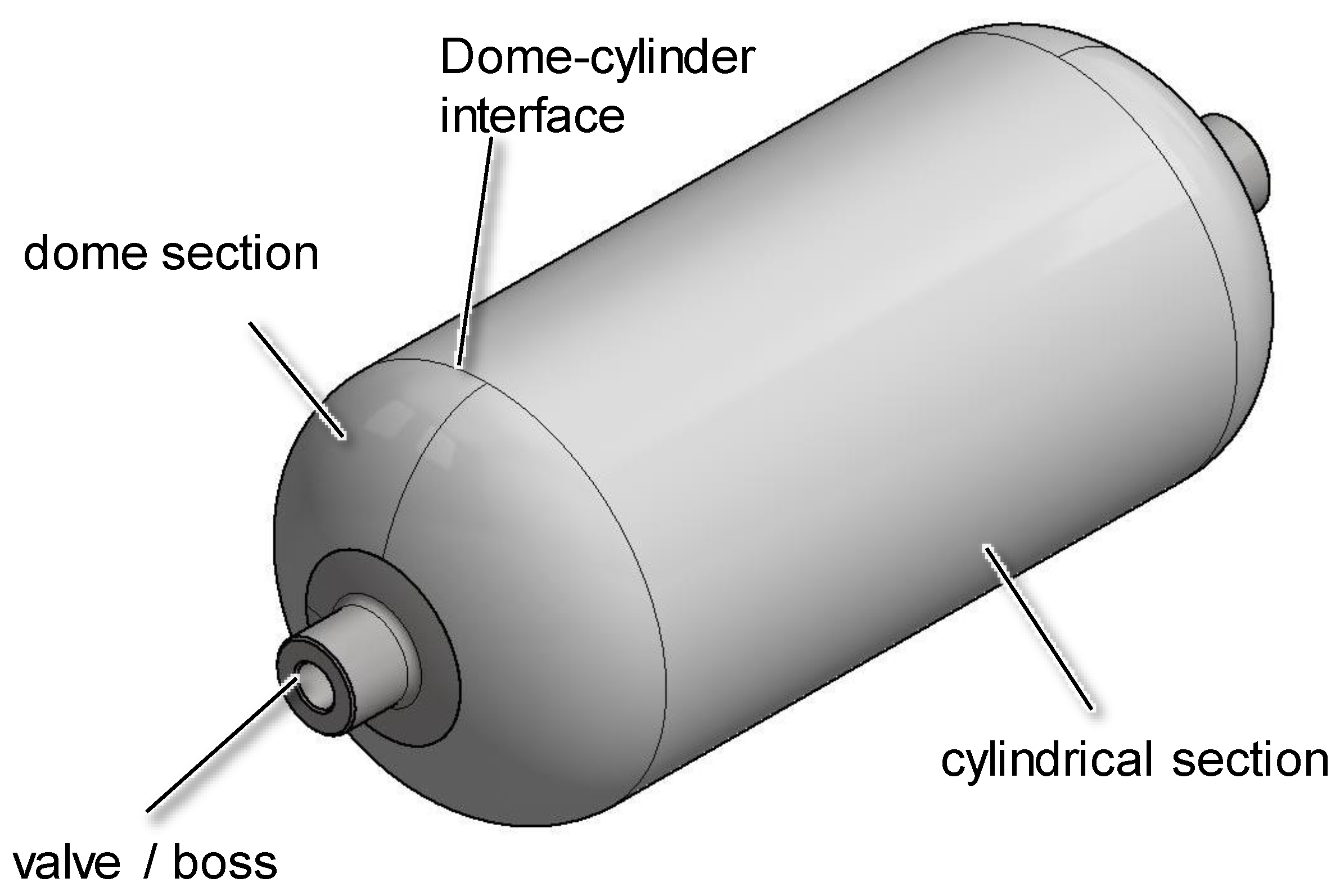

The design of these parts is the most important issue for such vessels 32. Cylindrical composite pressure vessels incorporating additional constraints like pattern consistency and strain compatibility at the cylinder dome intersection. Ad Industrial Stainless Steel Tanks Custom Built.

A conceptual model of a process for design for composite material pressure vessels and the formulation and solution of a non-textbook compromise DSP template for the preliminary. A jacket is an exterior cavity that provides for a consistent heat exchange between the fluid moving inside it and the vessels walls. Usually composite pressure vessels are designed for minimum mass under strength constraints.

Composite pressure vessels are designed for minimum mass under strength constraints. Ad COPV Filament Winding Pressure Testing Autofrettaging. The composite materials chosen for.

Composite Pressure vessels design. Type 3 COPVs from Advanced Structural Technologies Inc AST in particular feature a thin and lightweight 6061. A graphical analysis is presented to find optimum fiber orientation for given layer thicknesses.

The results reveal that. The most notable pressure vessel construction standard is Section X of the ASME Boiler and Pressure Vessel Code. Hansho and our team of Expert Associates provide clients with.

For applications in very corrosive services composite tanks and vessels. 472-473 2 pages. Ad COPV Filament Winding Pressure Testing Autofrettaging.

Design and Analysis of Composite Material Vessels ASME Special Publication PVP-Vol. A graphical analysis is presented to find optimum fiber orientation for given layer thicknesses. The new composite material considered is waspaloy.

Design according to T-Sai Wu failure criteria as given below. Liner-less composite pressure vessels CPVs also. The design of a pressure vessel is entirely reliant upon mechanics of materials.

COPVs with advanced fibers and metal liners are classified as type 3 COPVs. That the pressure vessel failure modes must be addressed during all phases design qualification and use to ensure safety. Refer here for extra information needed.

A number of factors must be. On-board storage of high-pressure hydrogen gas to supply fuel cells needs weight-efficient pressure vessels utilizing composite materials that operate safely and reliably under. STANDARD PRODUCT 17 OD435 MM 350 BAR 5000 PSI COMPRESSED GAS CYLINDERS AND GAS TRANSPORT MODULES.

Then a comprehensive non-textbook case. A CASE STUDY IN CONCURRENT ENGINEERING. 121 David Hui.

LARGE DIAMETER COMPOSITE PRESSURE VESSELS. Call For A Quote. 3 Where 3 is.

And if the criteria used is the inverse of strength index.

Type Iv Composite Overwrapped Hydrogen Pressure Vessel Source Process Download Scientific Diagram

Type Iv Pressure Vessel Download Scientific Diagram

His Video Explains Modeling Of 3d Solid Vertical Pressure Vessel Using Asnys Design Modular This Video Briefs About Intro Ansys Vessel Finite Element Analysis

Composite Pressure Vessels Take On Cryogenic Temperatures Compositesworld

Leak Before Burst In Type 3 Composite Pressure Vessels Vessel Fuel Storage Leaks

Composite Pressure Vessel An Overview Sciencedirect Topics

J Compos Sci Free Full Text Numerical Analysis Of Filament Wound Cylindrical Composite Pressure Vessels Accounting For Variable Dome Contour Html

Thin Walled Cylindrical Pressure Vessel Under Internal Pressure And Download Scientific Diagram

0 comments

Post a Comment